Construction of a small metal scourer production unit

1. Knitting

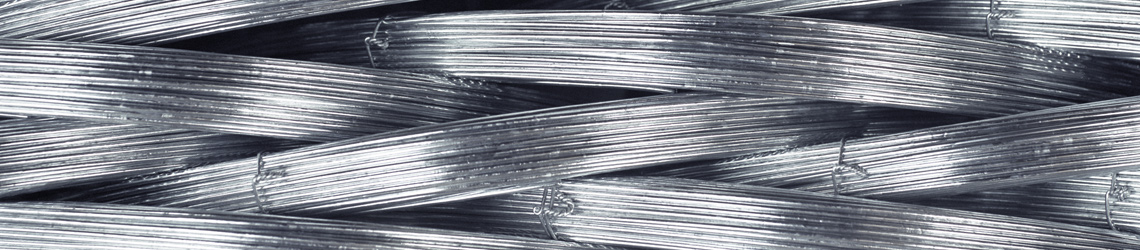

VOCO France Sàrl has developed its own robust knitting machines. They are simple to use and maintain. The production capacity of a knitting head is 220 machine rows per minute, i.e. 3.2 kilos of mesh tube per hour. With more than 50 years’ experience in the production of metal scourers, we have concentrated our efforts on the development of a supple, flat, laminated wire, galvanised or shiny copper-plated.

2. Preparation

he mesh comes out in the shape of a “stocking”. This is then cut according to the size and weight of scourers required. Preparation includes:

- Closing one of the ends

- Rolling the cut edge

- Sewing the opening shut

and may be done manually in-company or at home. We also offer simple cutting pedal-activated sewing benches.

There are three ways to manufacture scourers. The method that you choose depends on the size of the scourer and its intended use.

Simple method (2.8 MB)

Middle method (9.8 MB)

Premium method (9.8 MB)

3. Packaging

Metallic scourers are wrapped in different ways depending on distribution channel:

- In rings of 25 pieces (scourers on a wire)

- In small quantities in polythene bags for private use (2 or 3 pieces)

- In wholesale quantities (10–25 pieces)

Units are shipped in cardboard boxes or plastic bags.